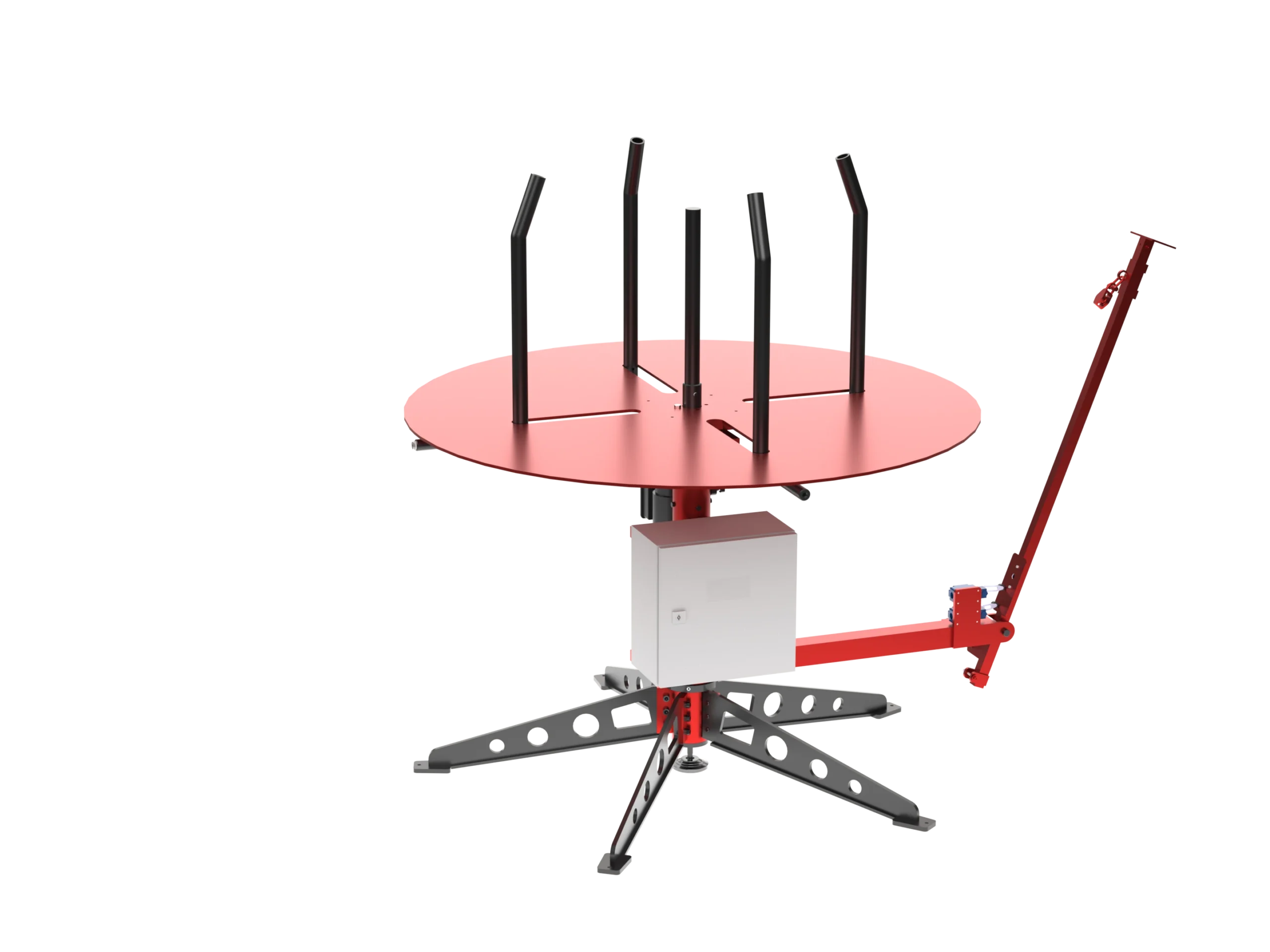

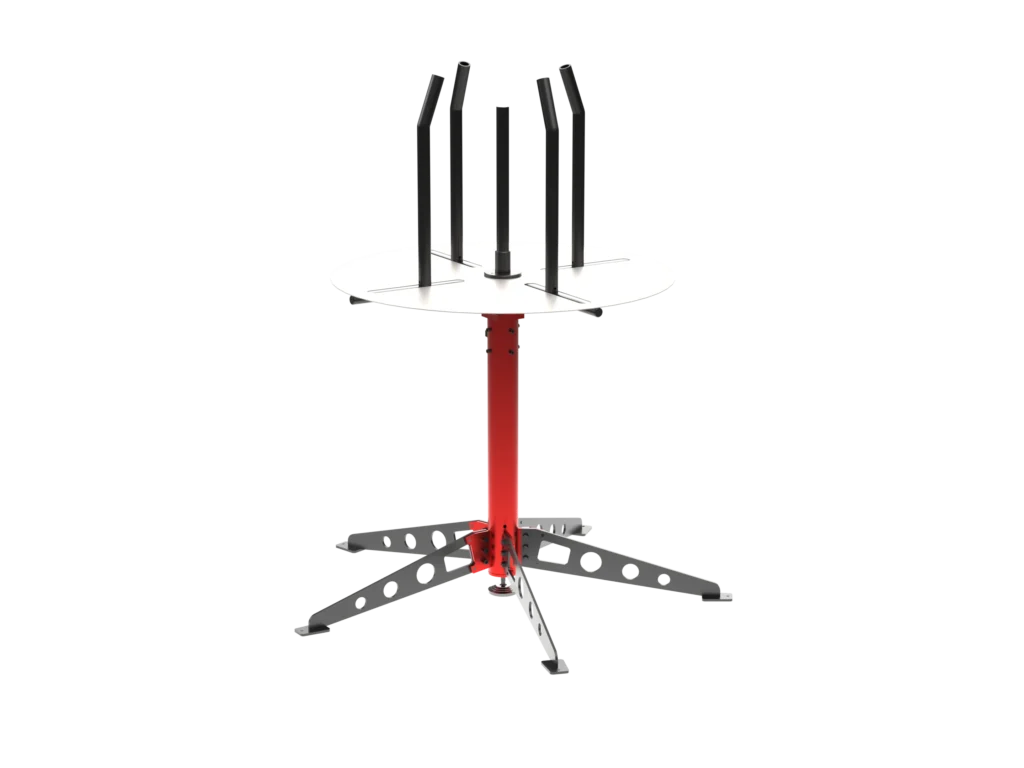

Material decoiler / mechanical

- Loadable up to 500 kg

- Coil material from Ø 1 – 13 mm

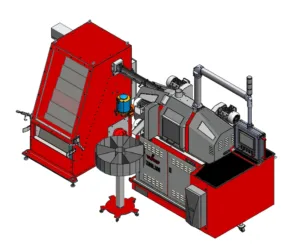

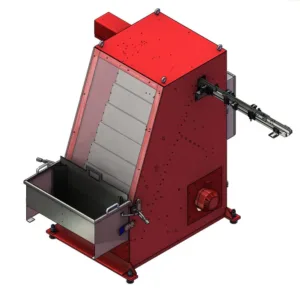

Step feeder

Step conveyor at the side or behind the machine. Single or double feeding of sections / turned parts.

- Design according to the customer requirements and range of parts

- Simple filling by docking the hopper car

- Very high filling speed

- Ideal also for longer parts

- Low-noise

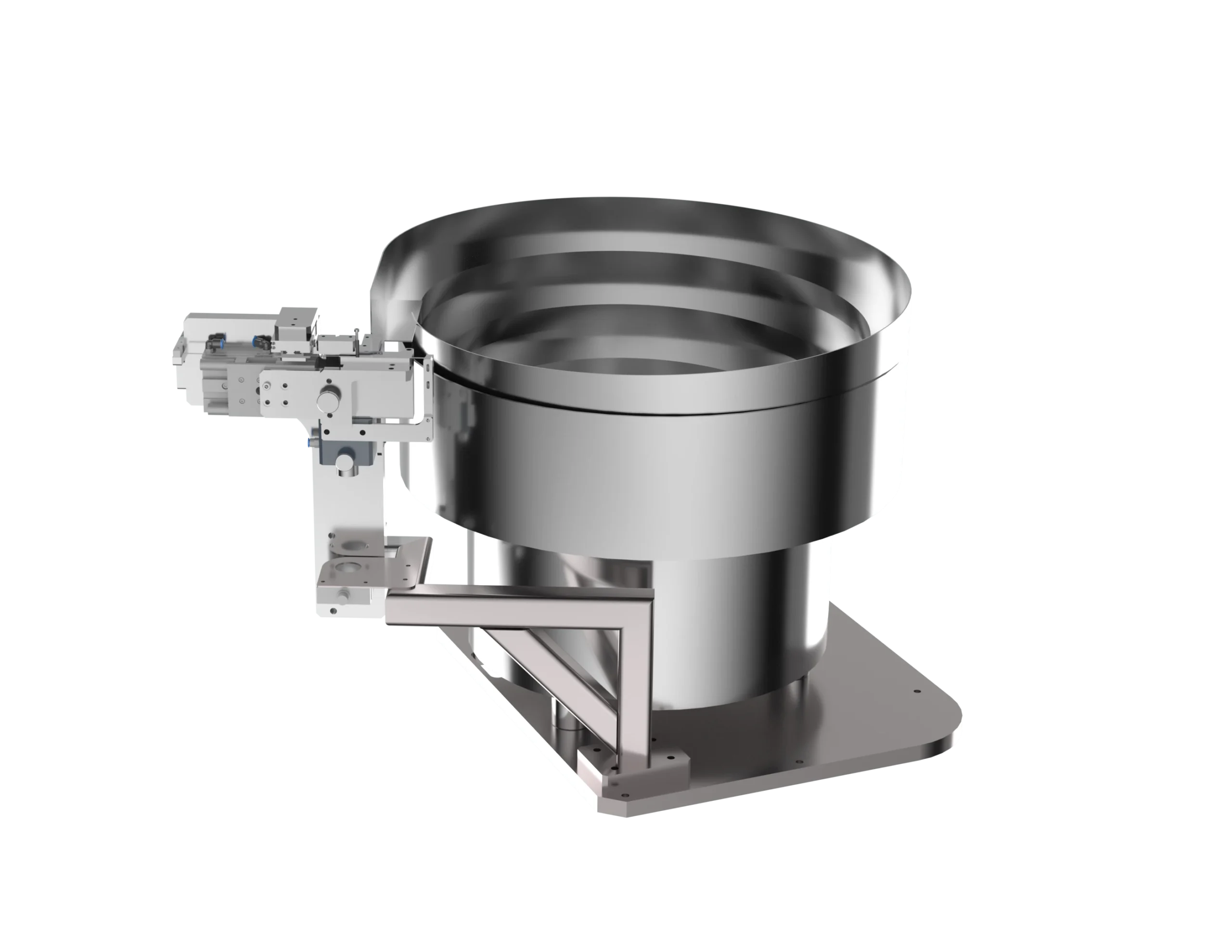

Oscillating feeding bowl

- Reworked parts / individual parts up to a Ø of 33 mm

- Pot is individually adapted to the parts to be processed

- Parts separation up to 52 parts / minute

- Feeding rail / parts separation

- Parts are fed into the machine room

- Pneumatic parts separation

- Pneumatic insertion of the parts to the clamping points

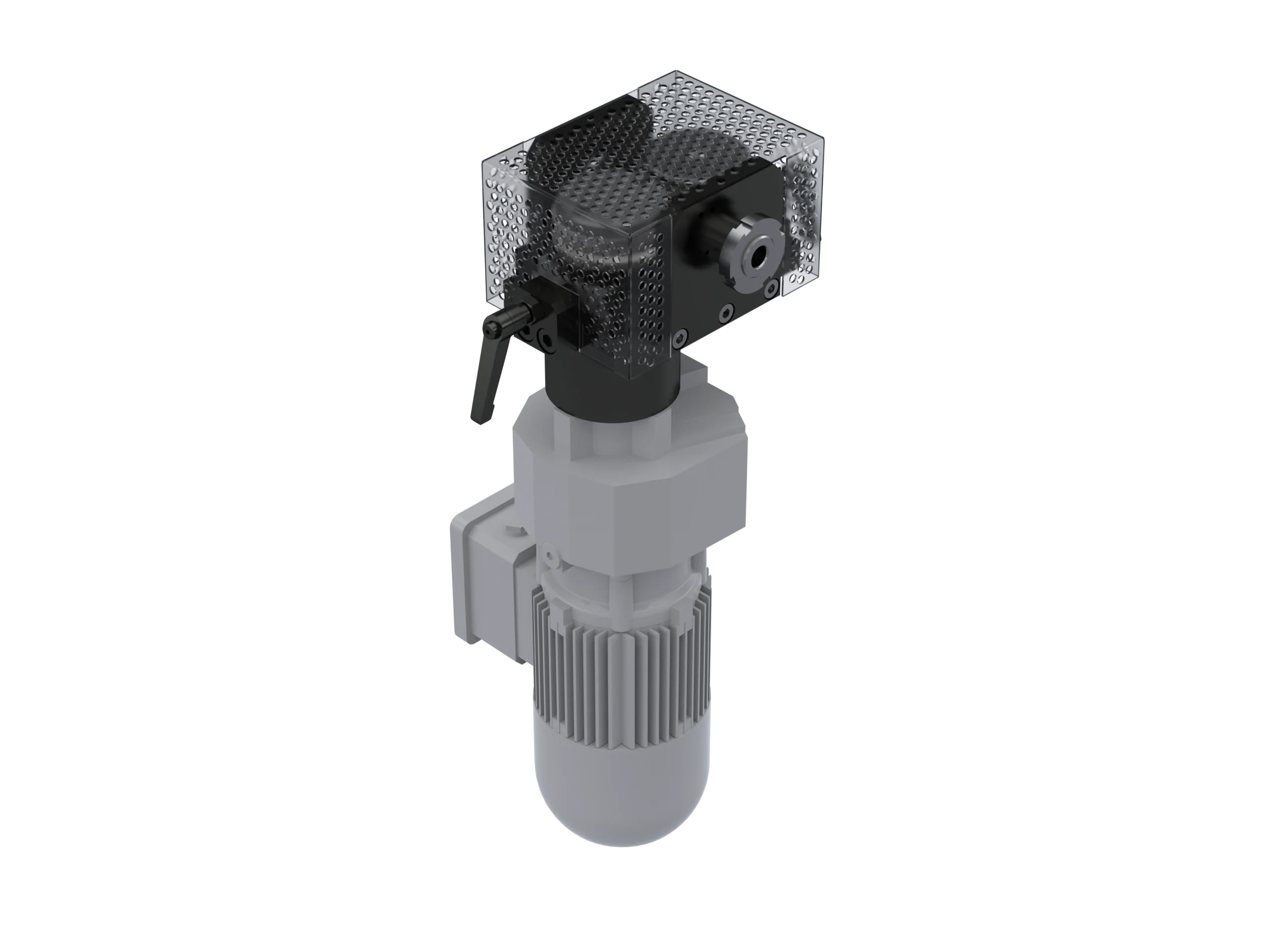

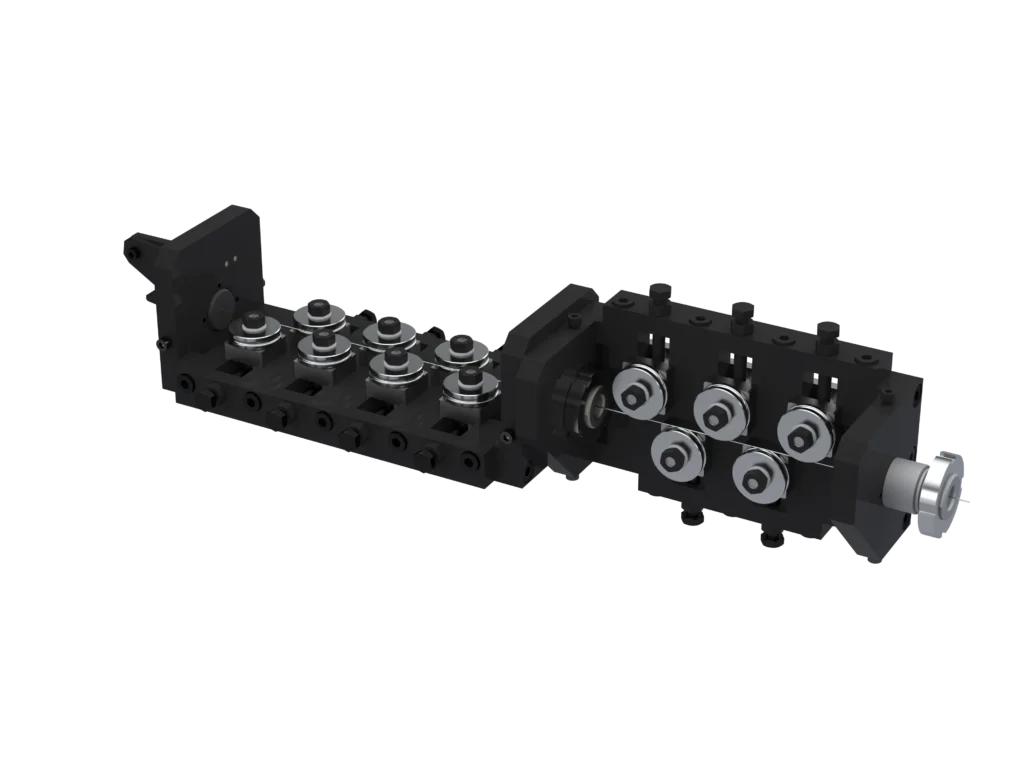

Cross straightening unit

- 12 straightening rollers, 7-fold + 5-fold

- Cross straightener small for wire Ø 1 – 4 mm

- Cross straightener medium for wire-Ø 4 – 8 mm

- Cross straightener large for wire Ø 8 – 13 mm

Rotating straightening unit

- Possibility of overstraightening for better straightness

- highly dynamic due to low moving masses

- for wire-Ø 1 – 6 mm, small with integrated inserter

- for wire-Ø 6 – 12 mm, large

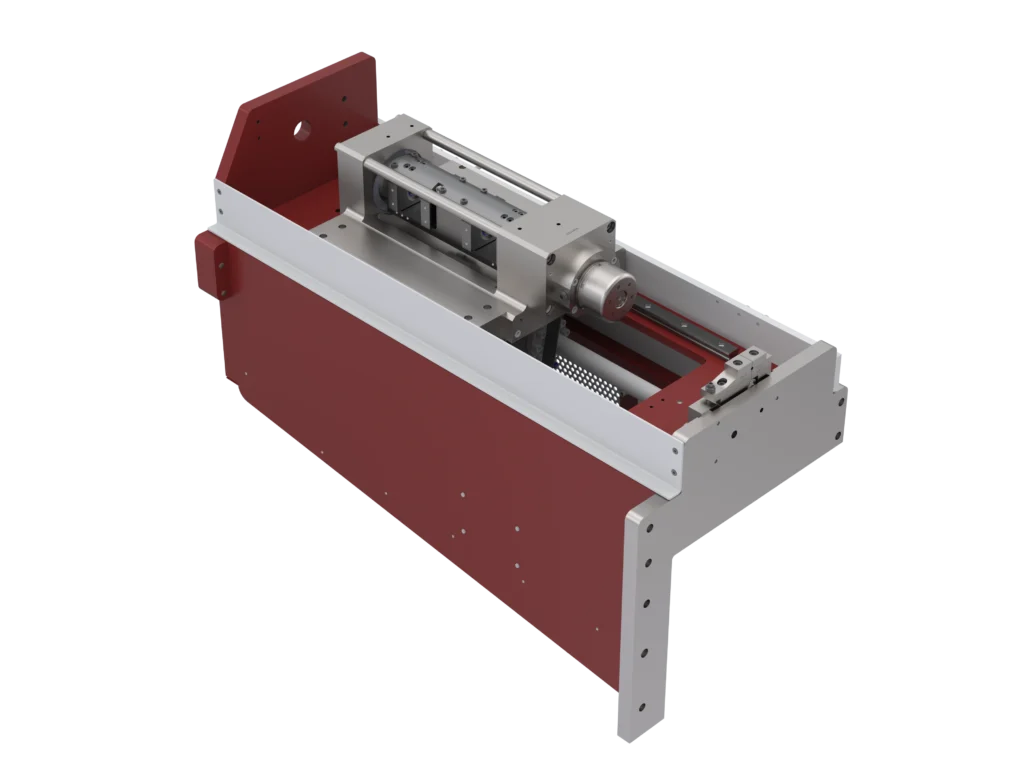

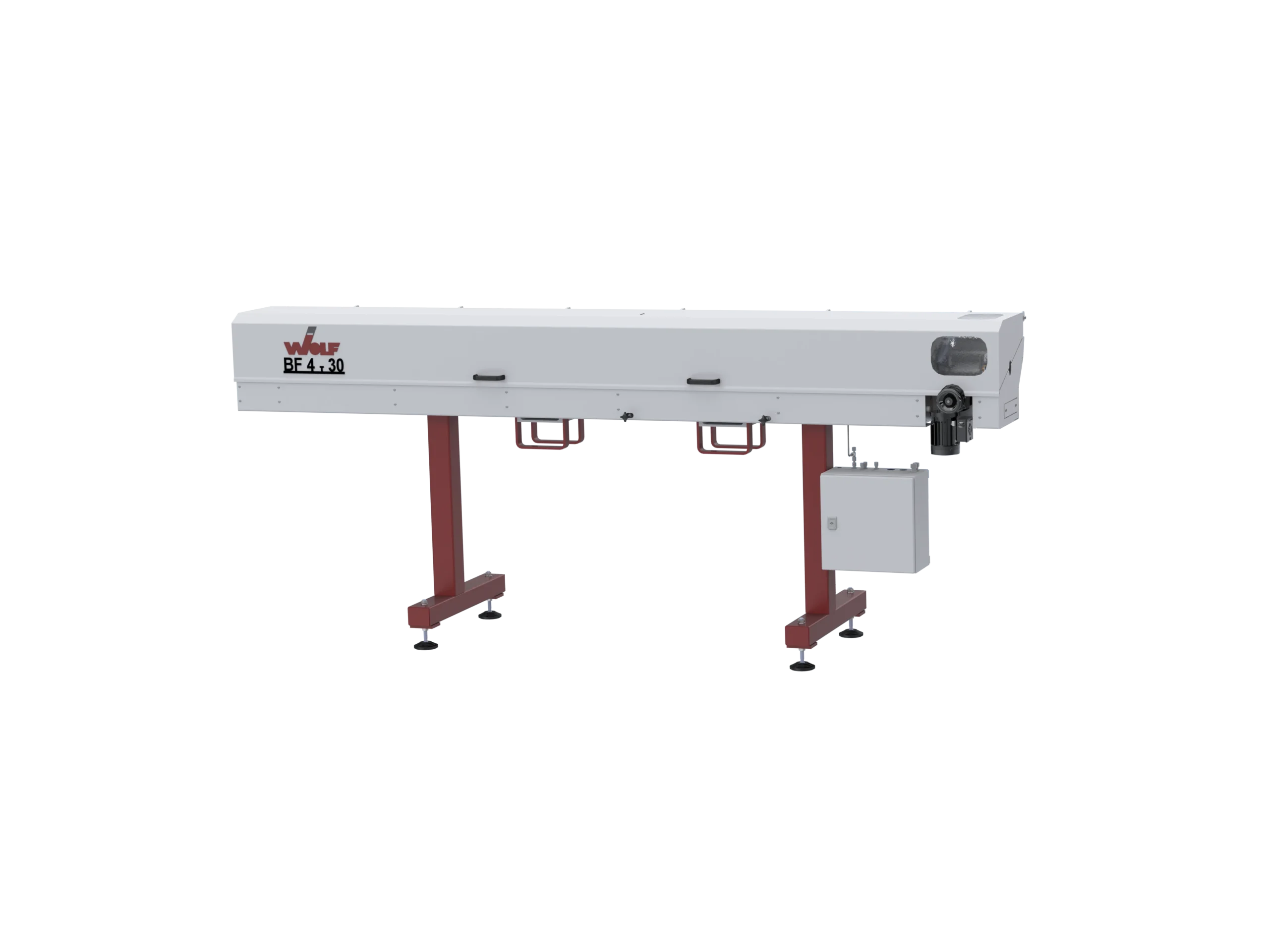

Bar feeder

Specially designed for fast bar processing. Guaranteed low residual bar length.

To reduce reloading for larger material diameters, bundle loaders can also be provided.

- Rod Ø from 4 mm to 30 mm

- Length of bar support: 450 mm

- Quickly convertible

quickly adjustable - Remaining lengths smaller than 60 mm possible

- Bar lengths: 3 m / 12,5 ft / 4,5 m / 6 m

Bar feeder options:

- Extension of the bar support up to 1,000 mm

- Sensor for bar minimum filling quantity with output of a message on the control panel

- Front stop for bar positioning

- Turning device for profile material

- Bundle loader

- Bar length can be processed from 120 mm

Robot unit

Loading and unloading via intergrated robot.