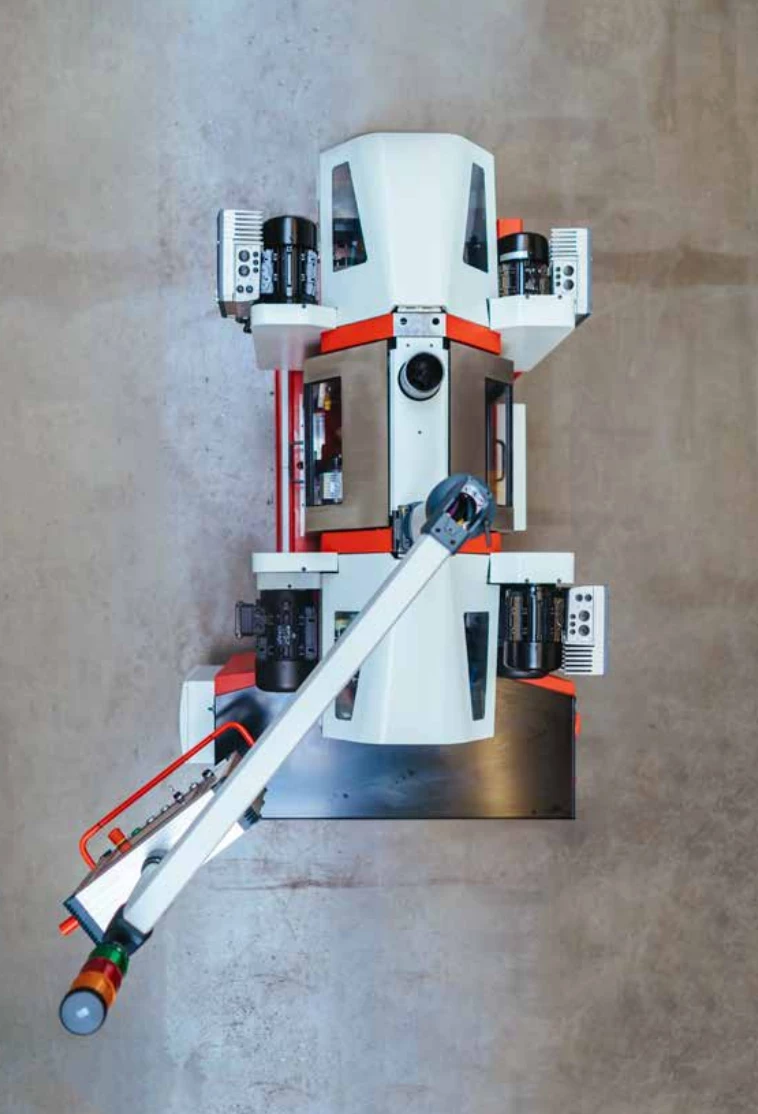

Wolf TMS 280

PRECISION - COMPACT - QUICK - FLEXIBEL

Rotary Transfer Machine

Wolf TSM 280 | TSM 280L | TSM 280 LS | TSM 280-45

PRECISION

- tolerance <5µm

COMPACT

- only 2,5qm floor space

QUICK

- up to 120 pcs. / min

FLEXIBLE

- up to 15 processing units

Your advantages at a glance:

The Wolf TSM 280 is a highly efficient rotary table transfer machine that allows for the execution of complex production processes on a single, extremely flexible production unit. Customised. Compact. Precise. A wide range of workpieces can be machined, be it cold extrusion parts, tubes, turned parts, straight turned parts or bar / coil stock – the Wolf TSM 280 guarantees reliable and cost-effective production performance for many different industries.

With its modular structure, the Wolf TSM 280 allows for customised process design – be it for a specific product or for an entire product family. A large number of additional units are available for the implementation of new processes.

Thanks to short set-up times and very good accessibility during tool change, a wide range of different workpieces can be produced on a single machine. The feeds, spindle speeds and thus also the cycle times of the workpieces to be manufactured can be set continuously.

Precision by the second!

This is what we offer:

Machine design

- Modular and compact basic model

- Extremely rugged welded assembly

- Three-point support ensures stability

- Vertical plate in different designs

- Mechatronics system: electric, hydraulic, pneumatic system

- Switch cabinet mounted at the machine

Installation / Transport

- Cost-effective shipment as a single unit (e.g. for retrofitting or repair)

- Easily moveable with forklift truck

- Integrated switch cabinet avoids complex mounting and installation work

- Plug out, pack in, transport, plug in – running

Production

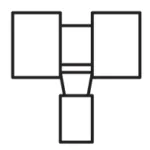

- Simultaneous machining of both sides is possible

- 2 – 120 parts/min

- Clamping sets with different diameters

- Easy retrofitting

- Double version available (dual infeed)

- LS variant for straight machining (replaces straight turning lathe)

- High-quality surfaces

Control

- Alternatively PLC or CNC control

- Very easy operation

- Optional tool monitoring

Maintenance

- Optional maintenance packages

- Remote maintenance via Internet (VPN), optional

The Wolf TSM 280 in action:

The all-in-one-machine

The Wolf TSM 280 is based on a rotary indexing principle and has been designed specifically for the production of parts for medium to large batch sizes (between 10,000 and 15 million parts). Thanks to its wide spectrum of use, the possibility of implementing different machining processes and the continuous controllability of all machining spindles, the TSM 280 can replace various machines and can be used even in confined spaces.

Versatile simultaneous machining. Reduced non-productive time.

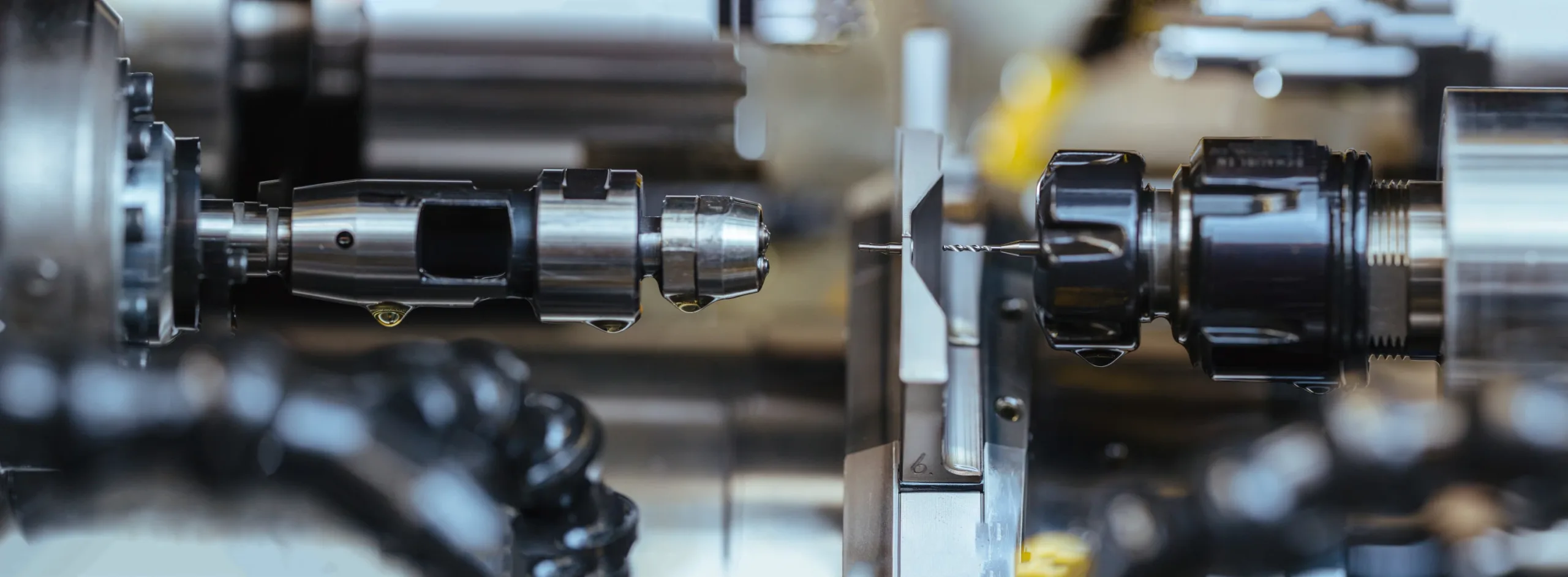

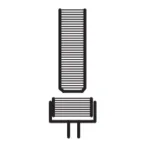

Simultaneous machining on both sides using up to 15 tools. The central element of the Wolf TSM 280 is the clamping plate that is arranged vertically in the centre providing 8 or respectively 16 hydraulically operated workpiece holding fixtures.

By default, the machining units are controlled mechanically and/or alternatively via CNC axes.

Adaptable units:

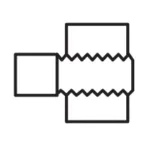

- Drill and lathe spindles

- Threaded units

- Plunge-cut units

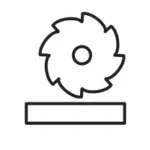

- Milling units

- Cross-bore units

- Embossing and pressing units

- Measuring and test equipment

- Special-purpose units

Your benefits at a glance:

- Highly Precise

- Fast

- Compact

- Economical

- Flexible

- Individual production according to costumer requirements

- Optional: SPS- or CNC-control

- Multiple simultaneous processes – reduced non-productive times

Technical data:

| Material cross section | TSM 280 | TSM 280L | TSM 280LS | TSM 280-45 |

| Coil stock | ≤ 13 mm | ≤ 13 mm | - | - |

| Bar stock | ≤ 30 mm | ≤ 30 mm | ≤ 30 mm | ≤ 45 mm |

| Part length | ≤ 80 mm | ≤ 200 mm | ≤ 300 mm | ≤ 60 mm |

| Clamping table | ||||

| Numbers of clamping positions | 8 / 16 | 8 / 16 | 16 | 8 |

| Clamping system | hydraulic | hydraulic | hydraulic | hydraulic |

| Clamping force | ≤ 25 kN | ≤ 25 kN | ≤ 25 kN | ≤ 25 kN |

| Number of unit heads | ≤ 15 Stk. | ≤ 15 Stk. | ≤ 14 Stk. | ≤ 14 Stk. |

| Feed | with cams hydraulic CNC control | with cams hydraulic CNC control | with cams hydraulic CNC control | with cams hydraulic CNC control |

| Work stroke | ||||

| With cams | ≤ 35 mm | ≤ 35 mm | ≤ 35 mm | ≤ 35 mm |

| Hydraulic · CNC control | ≤ 40 / 80 / 100 mm | ≤ 40 / 80 / 100 mm | ≤ 40 / 80 / 100 mm | ≤ 40 / 80 / 100 mm |

| Additional diameters and lengths on request.

Product information

TMS 280 | TSM 280L | TSM 280LS | TMS 280-45

Upon request, we will also be happy to send you documents by mail.